History of Calcium Carbide

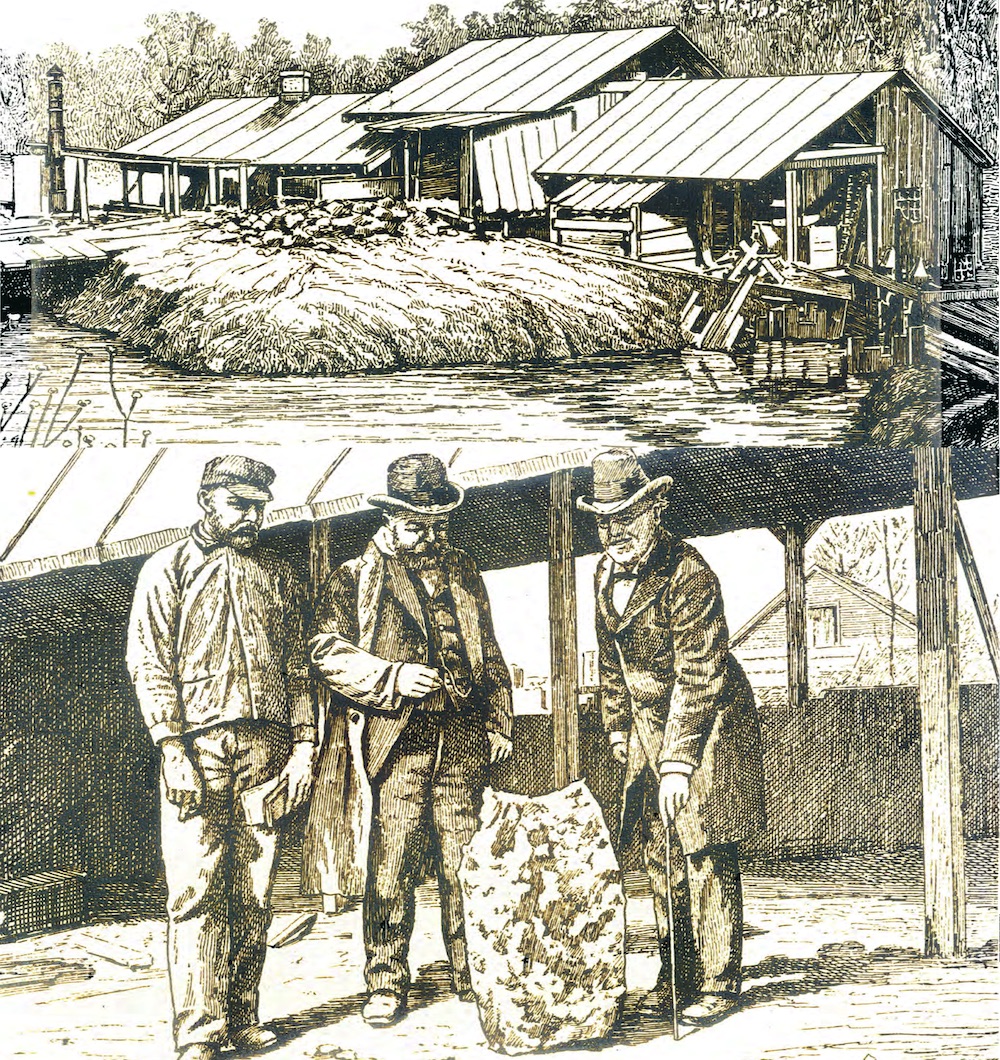

Trivia question: what is the top of the Washington Monument made from? Hint: It's not gold; in fact, it's aluminum. In May 1892, J.T. Morehead, T.L. Willson, and J.C. King, working out of Morehead's cotton mill in Spray (now Eden), NC, were looking for a new way to refine aluminum; aluminum at the time being more expensive than gold. The process they tested consisted of subjecting ore, lime, and coke to the intense heat of the new electric arc furnace, Willson being one of the furnace developers and owning the patents for its use. They failed to produce aluminum - but an industry rose from their discarded chunk of material that miraculously caught fire in a nearby field. Calcium carbide became one of the most important chemicals of the 20th century.

The history of calcium carbide is a fascinating tale of entreprenuership and technical savvy. After the stock market crash of 1893 nearly sunk the fledgling company, Willson and Morehead had to develop the markets for carbide themselves. Successful, Morehead returned to Spray to complete the manufacturing plant, going on to form the iconic Union Carbide Company, while Willson became involved in many carbide manufacturing concerns and applications. From one of Willson's industrial progeny sprung a calcium carbide manufacturing plant in Louisville, Kentucky.

Read more about carbide history here.

Source:

American Chemical Society National Historic Chemical Landmarks. Discovery of the Commercial Processes for Making Calcium Carbide and Acetylene.

(accessed March 18, 2015).

History of Rubbertown

When the natural rubber supply from Southeast Asia was cut off at the beginning of World War II, a consortium of companies involved in rubber research and production united with the U.S. government in a unique spirit of technical cooperation to produce a general purpose synthetic rubber on a commercial scale. In multiple locations, these companies, in collaboration with a network of researchers in government, academia, and industrial laboratories, developed and manufactured in record time enough synthetic rubber to meet the needs of the U.S. and its allies during World War II.

The rubber they developed and manufactured was an optimized Buna-S rubber, based on a technology that originated in Germany. The "Bu" in Buna stands for butadiene, which was principally obtained from calcium carbide generated acetylene.

Easy access to roads, rail lines, the Ohio River and raw materials led the U.S. Office of War Production to select Louisville for several plants to produce the synthetic rubber. In 1941, the government contracted with National Carbide to construct a calcium carbide/acetylene gas plant. Several other companies, including B.F. Goodrich, located rubber faciliies there, and by 1945 a consortium of five tire companies known as National Synthetic Rubber had opened a plant to support the war effort. The industrial western end of Louisville on the Ohio River is still known as Rubbertown today.

From a start of only 2,000 tons in 1942, by 1945 these companies were producing 920,000 tons annually of synthetic rubber nationwide. At the Rubbertown complex, by 1944, peak wartime production yielded 195,000 tons of synthetic rubber, employing more than 4,000 people.

The story of Rubbertown and its calcium carbide plant that was to become Carbide Industries LLC in the 21st century parallels the development of American economic might and the maturation of her basic industries.

Read more about our history here

and in the links below.

American Chemical Society National Historic Chemical Landmarks. U.S. Synthetic Rubber Program

. (accessed March 23, 2015)

Traditional Syntheses of 1,3-Butadiene

. (accessed Mar. 24, 2015)

Wikipedia: Rubbertown, Louisville

(accessed Mar. 24, 2015).

Timeline: History of Rubbertown (2011, March 22) in Louisville Courier Journal Archive.

(accessed March 23, 2015).